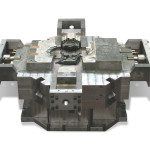

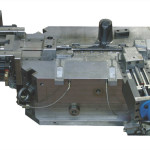

From the standard 2-plate tool “just open and close” to rather complex tool executions implementing a wide range of different possibilities and customized solutions:

- 3-plate tool with (multiple) central ingating

- inclined ejection system

- ingate trimming during tool opening

- pre – extraction of tool parts

- ejection system in fixed half

- solutions for x-cavity tools

- strategy for insert division or sub – insert

- underground slides with direct activation

- sliding parts activated by rack joints

- sliding parts activated by the ejection

- preparation for any type of vacuum valve

- jet-cooling

- cooling with curved supply channel

- additional hydraulic locking system for slide-blocks

- sealed tool technologies

- fast clamping and central ejection

- cast with inlays

- “cold” extracted inlays for undercut areas

- pre – extraction of core-pins